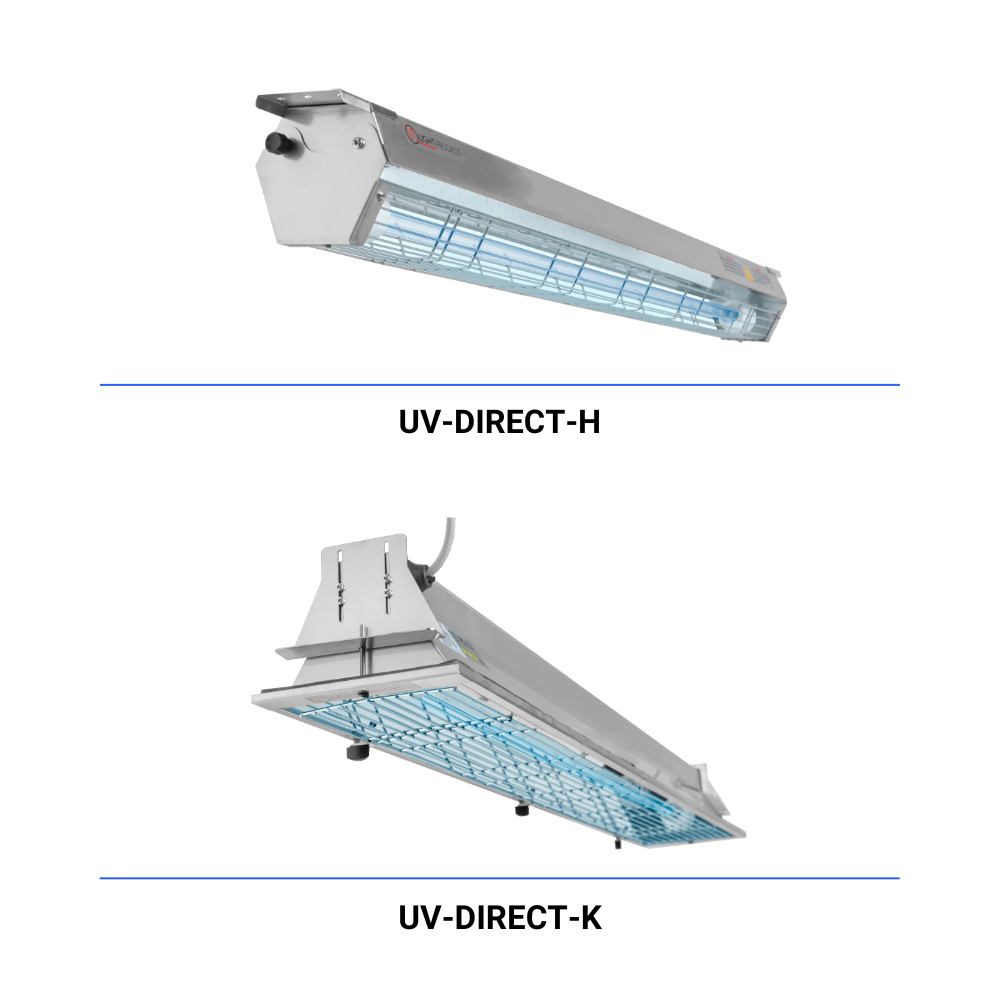

UV-DIRECT is composed of:

high-efficiency UV-C systems with the following features.

- Increased Disinfection Performance, with High-Output UV-C lamps (253,7 nm) and internalmirror bright aluminum reflector.

- Built to Last, in high-quality Stainless Steel AISI 304, all material tested for UV resistance.

- Protected, resistant to dust and splashes with an IP55 Rating.

- Integrate and Monitor, your operation with lamp failure alarm signals (“–EL” models).

- Advanced Management, with optional control board available for multiple lamp fixtures.

UV-DIRECT

UV-DIRECT allows for deep disinfection of air and surfaces in any type of environment. Traditional cleaning methods are often not sufficient to ensure high hygiene levels, which can only be achieved through the use of UV-C technology.

With UV-DIRECT, it is possible to obtain high levels of disinfection in a simple, immediate, and safe way, without generating heat, without the use of liquids, and without any side effects, to maintain high hygiene and quality standards.

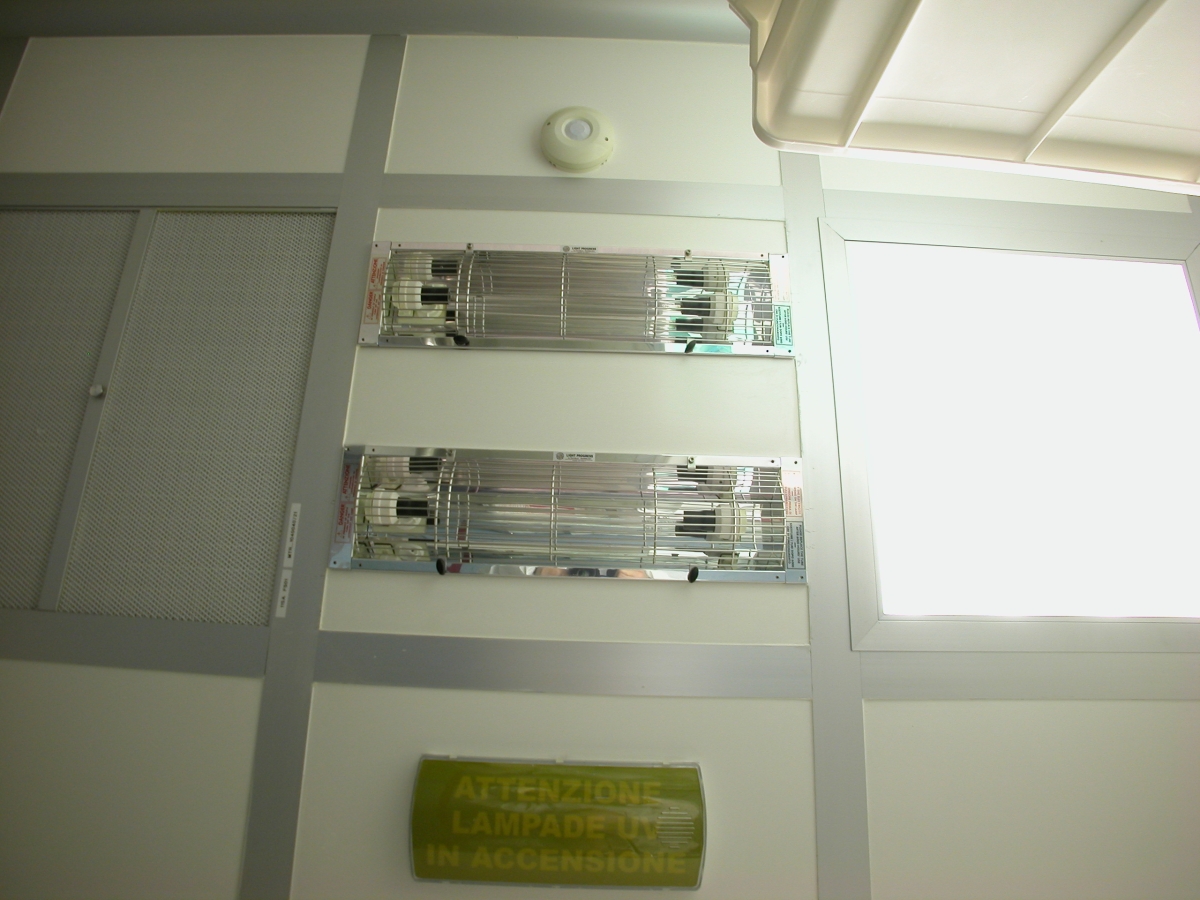

The device can be turned on during work breaks, always in the absence of personnel, to irradiate surfaces, which are then disinfected. In the environment, the natural circulation of air currents also allows for air treatment, which, purified of microbial load, creates an ideal and healthy environment.

UV-DIRECT-H-NX is equipped with a UV-C lamp and can be installed as a regular ceiling-mounted light fixture.

UV-DIRECT-K-NX is equipped with a UV-C lamp and is intended to be recessed into a false ceiling.

The disinfection level with UV-DIRECT achieves a reduction (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc., in just a few minutes of operation.

DISCOVER THE PRODUCTS

UV-STICK / UV-STICK (UL)

With UV-STICK, it is possible to achieve high levels of disinfection in a simple, immediate, and safe manner, without generating heat, without the use of liquids, and with no side effects, to maintain high hygiene and quality standards.

The device is installed like a regular ceiling-mounted light fixture and can be turned on during work breaks, always in the absence of personnel, to irradiate surfaces, which are then disinfected. In the environment, the natural circulation of air currents also allows for air treatment, which, purified of microbial load, creates an ideal and healthy environment.

UV-STICK-AL is made of aluminum, with an internal parabolic reflector in mirrored aluminum.

UV-STICK-AX is made of aluminum, with a flat internal reflector in mirrored aluminum.

UV-STICK-NX is made of stainless steel, with a flat internal reflector in mirrored aluminum. Also available in -UL version.

The disinfection level with UV-STICK achieves a reduction (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc., in just a few minutes of operation.

UV-PENTALIGHT

Operated through a remote control or dedicated control unit, equipped with a digital interface to manage ignition delay and treatment duration.

Automatic Safety Switch to avoid accidental exposure to people during UV-C disinfection.

Tested microbial reduction up-to Log6 with a 10 minutes treatment against Escherichia c., Salmonella T., Pseudomonas A., Staphylococco A., Klebsiella PN.

Portable Disinfection, five lamps, five wheels, digital controls, and one power cable ready for you to connect and disinfect large areas.

Optimized Performance, with Light Progress High-Output UV-C lamps (253,7 nm) and internal mirror bright aluminum reflectors.

Built to Last, with high-quality UV-Safe materials and robust control bar, body, and wheels.

Trusted Durability, IP55 Rating, available UVLON™ to capture broken glass and protect against temperature fluctuations, and four-sensor motion alarm.

Simple to Use, Digital interface manages switching ON, delays and treatment duration.

Easy to Maintain, the built-in hour counter let’s you know exactly when to replace lamps. No other maintenance is required.

Remote Control, to operate the device outside the target area for treatment

UV-STICK-NX-ST

UV-STICK-ST-NX allows for deep disinfection of air and surfaces in all types of food environments. Traditional cleaning methods are often insufficient to ensure high hygiene levels, which can only be achieved through the use of UV-C technology.

With UV-STICK, it is possible to achieve high levels of disinfection in a simple, immediate, and safe manner, without generating heat, using no liquids, and with no contraindications, thus maintaining high hygienic and quality standards.

The mobile device on wheels can be activated during work breaks, always in the absence of personnel, to irradiate the surfaces, which are then disinfected. In the environment, the natural air circulation also allows for air treatment, purifying it from microbial load and creating an ideal and healthy environment.

UV-STICK-ST-NX is made of stainless steel, with a double lamp and an internal reflective surface in mirrored aluminum.

The disinfection level with UV-STICK achieves a reduction (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc., within just a few minutes of operation.