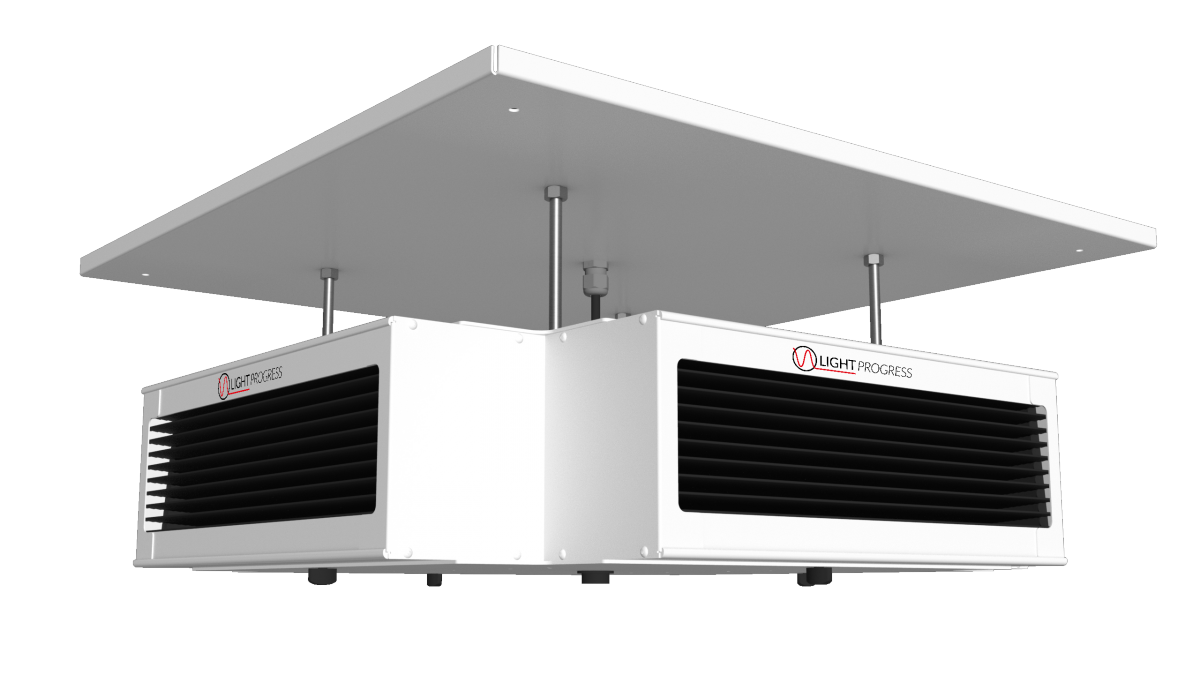

UV-FLOW-CL is composed of:

UV-FLOW-CL

The UV-FLOW .... CL is a controlled multidirectional flow device, with four powerful UV lamps inside and a narrow emission peak at wavelength of 253.7 nm. (nanometers), which has a strong germicidal effect against all micro-organisms (molds, bacteria and viruses).

There is also a parabolic, mirror bright aluminum surface, which generates UV rays parallel beams by reflection. These beams pass through a special black laminated grid that directs UV rays to form a unidirectional flow ("blade UV"). When installed according to the instructions, this device can be used in the presence of people for intensive and continuous air disinfection.

The UV-FLOW .... CL must be anchored to the ceiling to generate a special horizontal flow that will create a "zone of intense radiation" below the ceiling, which destroys all airborne microorganisms, due to natural convection of air.

The air, rich in microbes, is continuously treated and disinfected by the ultraviolet rays; a progressive decontamination of bacteria, viruses and molds is made, decreasing the possibility of bacterial, viral transmissions and contaminations in general.

Continuous operation ensures a permanent progressive healthy environment, especially in hospitals, schools, restaurants, indoor workplaces as offices, laboratories, etc..An extremely important disinfection activity can be done in hospitals intensive cares units, to prevent the spread of diseases such as TB and other transmissible pathologies through air.

DISCOVER THE PRODUCTS

UV-FAN

The big advantage of this machine is the ability to deal with the air of a room, 24 hours a day, without any contraindication for the staff present. Only a continuous disinfectant action can ensure the security to maintain the microbial load always under control; on the contrary, an intense, but uneven, disinfection results in a fluctuating level of germs present in the environment.

As a matter of fact, environments where food in processed need to be disinfected to keep high hygiene and quality standards, typical of this sector. With UV-FAN, it is possible to achieve disinfection of production, packaging, storage areas, etc. in a simple, immediate and safe way, without developing heat, without the use of liquids and chemicals and without any contraindications.

Conveyed by a silent built-in fan, the air in the room passes through the germicidal chamber of the purifier to be decontaminated from microbes, but also from chemical contaminants; in addition to the UV-C lamps, UV-FAN also contains an innovative Titan dioxide nano-particle filter TIOX ® with silver salts, which enhances the germicidal action of ultraviolet effect.

UV-FAN achieves the elimination (99%) of bacteria such as Bacillus, Coli, Clostridium, Legionella, Vibrio, Salmonella, Pseudomonas, Staphylococcus, etc. in just a few minutes of operation, its efficacy is also active against the virus causing COVID-19 possible spread.

Germicidal efficiency is certified by accredited laboratories (SINAL) by the Ministry of Health and the Institute of Hygiene at the University of Siena (the abatement of 3 logs of the T.M.C. has been certified).

.jpg)

UV-FAN-XS

- Steel body painted with epoxy powders or AISI 304 stainless steel (model ...-NX ).

- Selective UV-C lamp (at 253.7 nm.) with high efficiency and high UVC power, ozone-free for use in the presence of people 24/7

- Internal germicidal chamber made of ultra-pure mirror bright special aluminium with high UV-C 253.7nm reflectivity

- 24/7 Treatment continuity: use in the presence of people. ISO 15858 standard for safety of devices with UV-C lamps.

- Special photocatalytic titanium dioxide TiOx® technology (Registered Trademark of Light Progress Srl) for the elimination of organic and inorganic pollutants VOCs and NOXs.

- Complies with ISO 15714 standard that certifies the UV-C dose emitted and required to perform disinfection.

- Meets the noise standards of Directive 2006/42/EC <36db at 1mt

- Wall installation, floor installation kit available

- Porthole for visual inspection of the lamps, transparent to visible light but preventing the passage of UV-C rays

- Long cable with plug (2mt)

- Safety microswitch: that switches off the lamps if the cover is opened and lamp exposed, to perform maintenance in safety.

- CE marking (LVD 73/23 - EMC 89/336 - MD 93/42), ISO 60335-1-2

- Power supply with specific electronic ballast for UV-C lamps

- All materials used are tested to withstand intense UV-C radiation.

- Suitable for installation in class 1 - protected areas.

UV-FLOW-WL

There is also a parabolic, mirror bright aluminum surface, which generates UV rays parallel beams by reflection. These beams pass through a special black laminated grid that directs UV rays to form a unidirectional flow ("blade UV"). When installed according to the instructions, this device can be used in the presence of people for intensive and continuous air disinfection.

TheUV-FLOW-WL must be anchored at wall, at a fixed minimum height (see technical specification for details) from the floor to generate a special horizontal flow that will create a "zone of intense radiation" below the ceiling, which destroys all airborne microorganisms, due to natural convection of air.

The air, rich in microbes, is continuously treated and disinfected by the ultraviolet rays; a progressive decontamination of bacteria, viruses and molds is made, decreasing the possibility of bacterial, viral transmissions and contaminations in general.

Continuous operation ensures a permanent progressive healthy environment, especially in hospitals, schools, restaurants, indoor workplaces as offices, laboratories, etc..An extremely important disinfection activity can be done in hospitals intensive cares units, to prevent the spread of diseases such as TB and other transmissible pathologies through air.

UV-FLOW-WH

There is also a parabolic, mirror bright aluminum surface, which generates UV rays parallel beams by reflection. These beams pass through a black honeycomb laminated grid that directs UV rays to form a unidirectional flow ("blade UV"). When installed according to the instructions, this device can be used in the presence of people for intensive and continuous air disinfection.