UVC FOR GRAPE TREATMENT: A SAFER APPROACH TO SANITATION

The journey of grapes from vine to bottle is fraught with microbial challenges. Bacteria and molds can compromise the integrity of grapes and the wines they produce. Traditionally, grape sanitization involves chemical treatments that may have residual effects and can impact the environment. Enter UVC light, a non-chemical alternative that holds promise for enhancing grape safety without leaving behind unwanted traces.

Powdery mildew and other fungal diseases can significantly affect grapevines, leading to reduced yield and compromised grape quality. These pathogens thrive in warm, humid conditions and can spread rapidly, causing powdery white spots on leaves, stems, and clusters. Climate change and warmer temperature conditions can also create a more favorable environment for the growth and spread of the powdery mildew fungus.

Preventing powdery mildew and other fungal diseases on grapes using Ultraviolet-C (UVC) light is an innovative approach that can help mitigate the impact of these pathogens on grape vines.

GRAPE UV-C IRRADIATION IN THE POSTHARVEST PERIOD: A TOOL TO IMPROVE SENSORIAL QUALITY IN ‘CABERNET SAUVIGNON’ WINE

In a scientific study published on the Journal of Food Science and Technology (#59, 2022), Ultraviolet light-C (UV-C) was used in ‘Cabernet Sauvignon’ grapes in the postharvest period to improve the anthocyanin profile and sensory attributes in wine produced with irradiated grapes. Anthocyanins are important compounds in grapes and wine and significantly influence their characteristics. After winemaking and storage time (6 months), ‘Cabernet Sauvignon’ wine produced with grapes irradiated with UVC light presented higher perception scores for visual color, aroma, taste, and was preferred by the tasters over the wine produced with non-irradiated grapes.

UVC APPLICATION IN WINE PRODUCTION CELLARS: ELEVATING HYGIENE STANDARDS

Wine production cellars are hives of activity, where the transformation of grapes into the finest vintages occurs. However, this environment can also be a breeding ground for contaminants that threaten the quality of the end product. Maintaining the cellar disinfected is essential to prevent spoilage, off-flavors, and also the formation of mold on wooden aging barrels and other containers and equipment. Here, UVC light emerges as a powerful tool to bolster hygiene protocols.

Cellar cleaning is an intricate process that involves meticulous attention to detail. By incorporating UVC light, winemakers can enhance their cleaning and sanitation practices, targeting microbes that might persist even after conventional cleaning. UVC light's ability to inactivate microorganisms directly complements traditional cleaning agents and practices, ensuring a higher level of sterilization.

Benefits of UVC Application in Wine Cellars:

- Microbial Control: UVC light can reach nooks and crannies that might be challenging to access during manual cleaning, effectively reducing microbial populations.

- Complementary to Cleaning: UVC light works in synergy with traditional cleaning agents, creating a more robust cleaning and sanitation regimen.

- Time Efficiency: UVC treatment can save time by reducing the need for extended downtime during thorough cleaning sessions.

- Quality Assurance: By minimizing the risk of contamination, UVC contributes to consistent wine quality and sensory characteristics.

IN CONCLUSION: A BRIGHT FUTURE FOR GRAPE AND WINE SAFETY

The integration of UVC light into grape treatment and wine production cellars marks a significant step forward in the quest for food safety and quality. Its ability to combat microorganisms without relying on chemicals, positions UVC as an environmentally conscious solution with far-reaching implications.

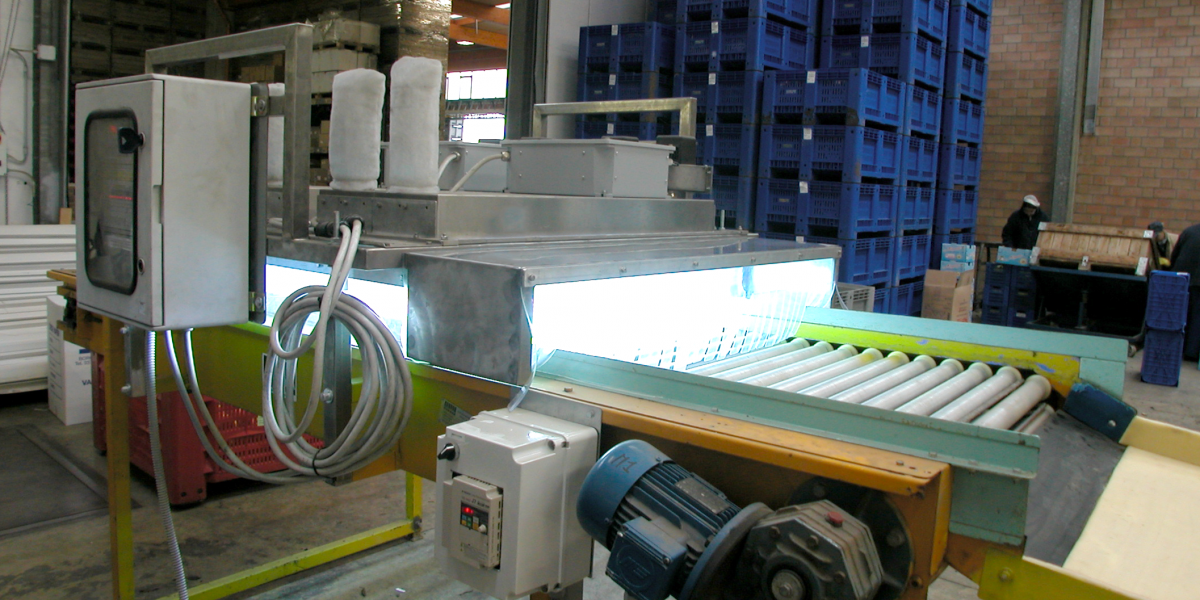

However, successful implementation hinges on meticulous calibration of UVC dosage, exposure time, and consideration of cellar layouts. Light Progress devices for food processing and surfaces and environmental UV-C irradiation are specifically designed for such kind of treatments.

Get in touch with our product specialists for a design proposal and a quote.