5 minutes read, PDF version available: DOWNLOAD PDF

A PRACTICAL, INTEGRATED TOOL DESIGNED FOR HVAC ENGINEERING

When designing a UV-C system for HVAC applications, the difference between a generic solution and a truly effective one lies in the quality of the sizing process. UV dose, irradiation, exposure time, and system configuration must be fully aligned with the real operating conditions of the installation.

UV-CALC is the Light Progress configuration software developed to support designers, OEMs, and partners in the selection of UV-C lamps and related components, offering a technical yet intuitive approach, accessible online and easily integrable into existing design workflows.

What is UV-CALC

UV-CALC is an HVAC configuration tool for UV-C systems, specifically designed for applications in Air Handling Units (AHUs) and air ducts, with a focus on:

- Air disinfection (AIR)

- Coil disinfection (COIL)

- Combined AIR + COIL configurations

The goal is to deliver clear and actionable design outputs: which models to use, how many lamps are required, and how to configure the system according to the actual application parameters.

From disinfection target to system configuration

UV-CALC allows users to easily define the required disinfection level (Good / High / Max), ensuring that system sizing is aligned with project objectives and expected performance.

Based on the input data, the software supports:

- selection of the most suitable UV-C lamp models

- calculation of the required number of lamps

- optimal configuration of power supply options

- selection of installation accessories and mounting components (e.g. extension cables, mounting kits)

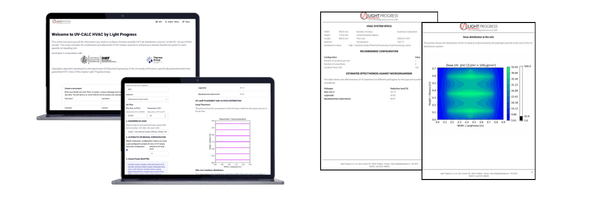

Charts and outputs: design transparency inside the air duct

One of the key strengths of UV-CALC is its engineering-oriented approach. The software does not only provide a final result, but also visual tools to support system validation and design confidence.

Depending on the configuration, UV-CALC can generate:

- UV-C irradiation and dose distribution charts inside the air duct, calibrated to the input data

- a graphical application layout for AHUs and air ducts

- airborne microbial reduction estimation, including references to tuberculosis, legionella, and SARS-CoV-2

- PDF output reports, ready for technical documentation and sharing

Complete BOM: UV-C systems, mounting kits and accessories

UV-CALC generates a complete Bill of Materials (BOM), supporting quotation and procurement activities and including:

- UV-C systems

- mounting kits

- installation accessories and components

This enables a smoother transition from calculation to implementation, reducing errors and saving time.

Online and integrable: the BLACKBOX version (DLL)

In addition to the online calculator, UV-CALC is also available as a BLACKBOX software package.

- developed as a .NET DLL

- usable as a stand-alone module

- fully integrated into AIRCALC and AIRCALC NEXT

This solution is ideal for partners and OEMs looking to embed UV-C configuration logic directly into their own calculation tools and engineering workflows.

Want to see UV-CALC applied to your project?

.png)

.png)