PROJECT OVERVIEW

In the challenging operational landscape of gas oil platforms, maintaining optimal air quality within the ductwork is critical for personnel health, equipment longevity, and overall operational reliability. Our client, a leading player in the oil and gas industry, recognized the need for advanced air treatment solutions and approached us to tailor a product for their specific requirements.

CLIENT CHALLENGES

- Harsh offshore environment

- Continuous exposure to contaminants

- Limited access for maintenance

- Need for manual control during maintenance activities

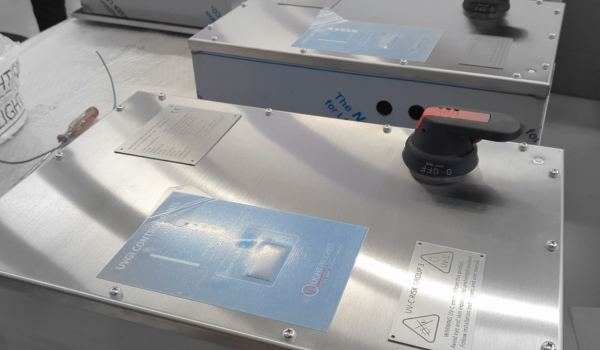

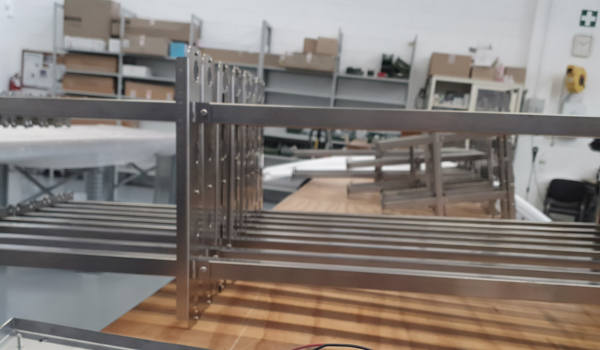

We developed a customized UVC air treatment system, UV-RACK-CS-IMT-16, addressing the unique challenges faced by our client. The key features of the product were meticulously designed to meet the stringent requirements of gas oil platforms.

KEY FEATURES

Stainless Steel 316L Construction: Enhanced corrosion resistance for prolonged durability in marine environments. Mitigates the risk of microbial-induced corrosion.

Stainless Steel Product Labels: Labels engineered from stainless steel to resist extreme environmental conditions, ensuring long-lasting product identification and readability.

Higher IP Rating on Control Boards: to safeguard internal components against moisture, dust, and other environmental factors.

External Handle for Manual UV Treatment Control: An external handle designed for manual control of the UV treatment system. This feature allows personnel to turn the system on/off manually during maintenance inside the ducts, ensuring safety and flexibility in operation.

Bespoke Manufacturing: Customization options, including material selection and additional features, tailored to meet the client's specific needs. Flexibility to adapt the product according to the unique requirements of each gas oil platform.

The original equipment design is from the UV-RACK series, also available in a UL version. Further details and specs available on the products page: https://www.lightprogress.it/en/products/uv-rack_4.html

BENEFITS AND RESULTS

Improved Air Quality: The UVC air treatment system effectively neutralizes airborne pathogens, contributing to enhanced indoor air quality for personnel working in confined spaces.

Reduced Downtime: Manual control through the external handle facilitates swift maintenance activities without causing disruptions to the overall operations.

Extended Equipment Lifespan: Stainless steel construction and advanced corrosion resistance features contribute to the longevity of the UVC air treatment system, minimizing the need for frequent replacements.

Enhanced Safety: The customized solution prioritizes safety by providing manual control, ensuring that maintenance personnel can safely perform tasks within the ducts without compromising on air treatment.

CONCLUSION

Our tailored UVC air treatment solution, UV-RACK-CS-IMT-16, has proven to be a pivotal asset for gas oil platforms, addressing unique challenges and contributing to a healthier, safer, and more efficient operational environment. As we continue to innovate, our commitment to delivering solutions that withstand the rigors of offshore environments remains unwavering.

Explore how our tailored solutions can elevate your air quality standards. Contact us for a consultation: info@lightprogress.it