In restaurants, large kitchens, community kitchens, shopping malls, office buildings, hotels and food courts, keeping the kitchen-hood and the exhaust systems ducts clean and hygienic, is crucial.

It allows to prevent and eliminate annoying problems of efficiency of the entire ventilation system and at the same time ensures the maintenance of a low risk of fire.

Beside this, challenges associated with reducing odors produced by cooking food are wide spreading and represent an increasingly issue in all restaurants.

ANNOYING SMELLS PRODUCED BY COOKING FOOD

The substances responsible of odors while cooking food mainly include fat-acids, aliphatic and aromatic hydrocarbons, aromatic amines and aldehydes. The type and quantity of pollutants emitted depend mainly on what kind of product has been cooked, the cooking methods and the means used for cooking. There are many ways to filter odors, but there are no specific rules on “olfactory pollution”.

Odor is a complex phenomenon to understand, not just for the wide range of potentially odorous substances, but mainly because the ability of a substance to be perceived by our olfactory system depends on different aspects that are both objective (volatility, water solubility, etc) that subjective (physiological and psychological of the observer) but can also involve the environment (temperature, pressure, relative humidity of the air, speed and direction of the winds). This means that the same substance, at a distance from the source, is perceived differently by different people.

The odorigenic compounds can constitute an important friction point between the restaurant / hotel /catering and the surrounding environment, since smells are able to spread in large areas without that anybody can carry out resolutive interventions to contain it avoiding the exaxperation of the people involved.

GREASE AND RISK OF FIRE

During food cooking phases, fats pollutants are also generated and grease layers will form inside the kitchen-hood and the exhaust system ducts. According to the National Fire Protection Association (NFPA) in the USA, the majority of restaurant fires originates on kitchen cooking appliances and flare into the kitchen exhaust system laden with grease, and then onto the building roof. So besides the inconveniences generated by unpleasant smells, fats deposits are very dangerous for fire risks, and for this reason continuous maintenance operations are necessary or even better, preventing the formation of grease into the exhaust system ducts.

UV-C LAMPS TO PREVENT RISK OF FIRE AND ANNOYING SMELLS

UV-C lamps are special lamps which light emissions are capable of breaking the bonds of fat compounds by “breaking” them down into simpler molecules already present in the air (such as H2O, CO2, etc.). This is scientifically called "cold combustion".

So UV-C technology is the most effective way to reduce the grease deposition on the ductwork and pollution in the exhaust system ducts.

The advantages of using this technology go far beyond their effectiveness and, among other things, allow to:

- REDUCE RISK of fire

- REDUCE COSTS for the maintenance of the kitchen-hood and the exhaust system ducts

- REDUCE USE of chemicals for sanitation

- ENSURING SAFETY of the cooking area

- ENSURING CLEANING and hygiene of the cooking area

TESTED EFFECTIVENESS OF THE LIGHT PROGRESS “UV-SMELL” PRODUCT

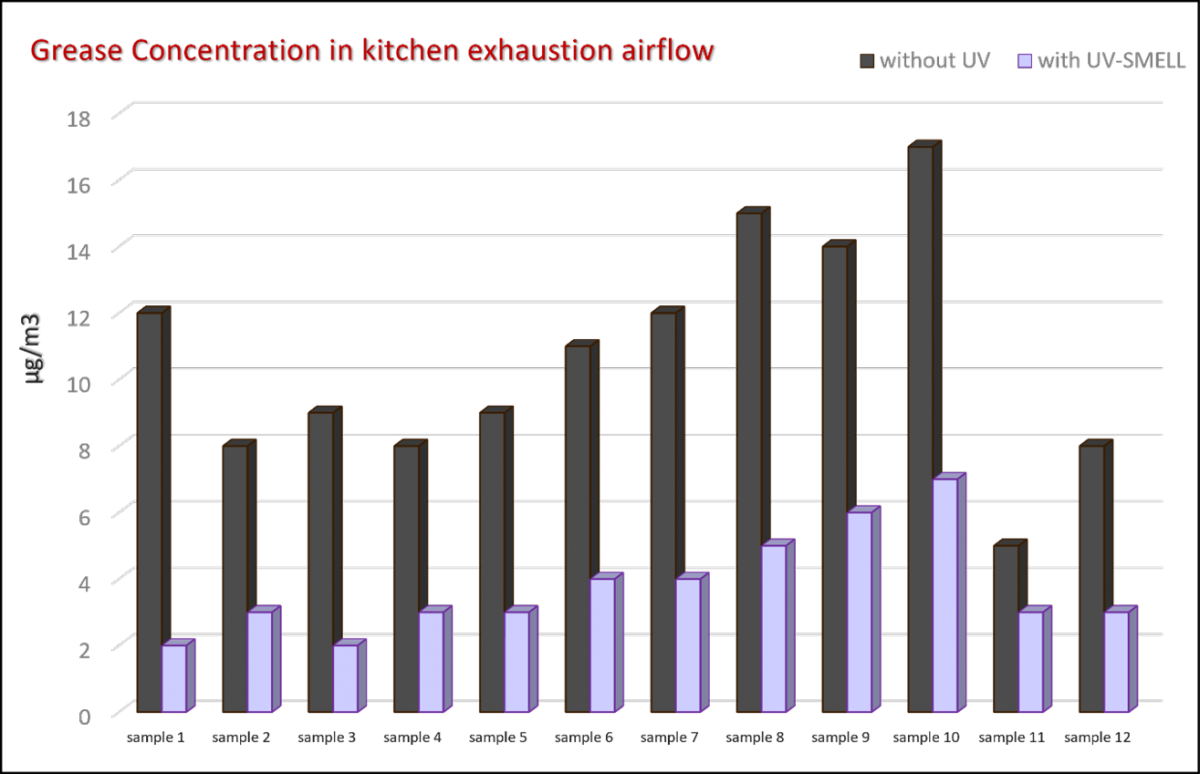

If it is difficult to test the effectiveness in reducing odors, since these are perceived differently from person to person, it is however possible to carry out tests to verify the effectiveness of the UV-C technology in reducing the formation of grease inside the kitchen-hoods and smoke evacuation systems.

We run an internal test carried out on 12 different UV-C applications in professional kitchens. The test shows that in each of the 12 applications, the concentration of grease inside the hood is significantly reduced if a UV-C section is installed inside the hood, and specifically for our study a "UV-SMELL" section, designed and manufactured in Italy by Light Progress Srl. The “UV-SMELL” systems can be installed in hoods that treat from 1,000 mc / h up to 4,800 mc / h of exhausted air and are therefore a flexible solution for various systems, both new or existing.

COMBINE UV-C WITH OZONE, TITANIUM DIOXIDE AND CARBON FILTERS FOR ADDITIONAL EFFICACY

So the ideal ventilation system in a large professional kitchen should include a portion containing UV-C lamps, possibly together with lamps with Ozone emissions and filtration systems in Titanium Dioxide (TiO2) and Silver Salts in order to achieve a higher efficiency.

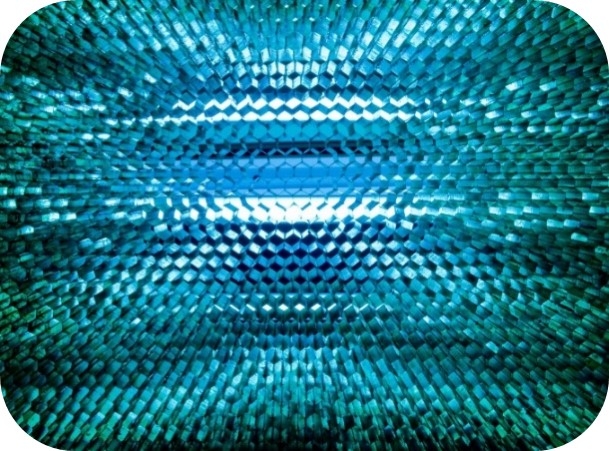

A first combination is with TIOX® honeycomb filters, an original Light Progress filter coated with nano-structured Titanium Dioxide (TiO2) and Silver Salts that, in combination with the very high UV-C power emitted by lamps, is an excellent photo-

catalyst that degrades pollutants and organic and inorganic compounds (SOV, NOx and VOC volatile organic compounds, nitrogen oxides).

catalyst that degrades pollutants and organic and inorganic compounds (SOV, NOx and VOC volatile organic compounds, nitrogen oxides).Consequently, TIOX® filter performs further oxidation of polluting particles, and contributes significantly to the deodorizing action of UV-C. Installation is very easy and safe, the only precaution in the is to mount it downstream of mechanical filters that micronize fat molecules like common mesh or labyrinth filters.

A second combination for the maintenance of cleanliness and a prolonged effect on the elimination of odors, is the application of UV-C lamps with Ozone emission. Some lamps in fact can be made with a special transparent quartz at a wavelength of 180 nanometers, which is able to "transform" the molecules of Oxygen into molecules of Ozone (O3). As soon as ozone comes into contact with an organic matter, an oxidation reaction is triggered. Basically, molecules are oxidized, they are transformed into harmless molecules, thus a strong reduction of any form of bad smell.

The application in the kitchens’ ventilation channels is very effective in eliminating odors precisely because ozone is able to "follow" the smells along the ductwork, eliminating them before they are released outside. The properties of ozone are both ultra clean and persistent over time; ozone is in fact a highly unstable molecule, which tends to re-transform into oxygen soon.

Finally, the application of UV-C technology, stand-alone or in combination with Ozone emissions and Titanium Dioxide filters, perfectly combines also with activated carbon filters. Not only these technologies fight odors effectively together, but carbon filters are greatly improved from the application of Ultraviolet rays, which increase their durability and efficiency.

A SAFE TECHNOLOGY, SUITABLE FOR NEW APPLICATIONS AND RETROFIT APPLICATIONS

The installation of the above mentioned technologies is nowadays pretty widespread inside professional kitchens. There technologies are safe and easy to be installed, despite some best-practice and recommendations shall be followed.

The application of UV systems is as efficient as it is closer to the source of the smoke. Being able to mount the UV systems immediately after the hood in fact enables not only to keep the surfaces clean from the initial stages, but the air "free" from fat compounds leaves no deposit in any part of the ventilation duct.

The optimum air speed must not exceed 3 m / s

Applied in the hood, it is necessary to ensure that the UV , system is positioned so that the filters shield the outflow of the rays towards the operator and provide a microswitch for system easy OFF.

Using ozone, it is always advisable to add a pressure switch that automatically switches off the UV system in the event of a stop in ventilation to guarantee operators’ safety.

In the case of outlets at street level and the application of UV + Ozone systems, it is important to make sure that the Ozone has completely "turned back" into oxygen before the air comes out in the street. Usually a few meters of channel are required for this to happen, otherwise the application of a second UV-ONLY system at the outlet can guarantee its complete elimination, UV-C rays "help" the O3 molecules to turn into O2.

View all related products for odor & grease reduction for industrial kitchens at: https://www.lightprogress.it/en/solutions/grease-odor-removal/

.jpg)