Insights from the Latest EnergyPlus Simulation Study by PNLL and Berkeley Lab.

ASHRAE Standard 241 connects the reduction of airborne disease transmission directly to the amount of “equivalent clean air” delivered indoors. In simple terms, equivalent clean air is air that has been cleaned of infectious aerosols — whether through ventilation, filtration, germicidal ultraviolet (GUV) technologies, or portable air cleaners. Delivering this clean air always requires energy: either as electricity for devices or through additional heating and cooling loads on the HVAC system.

While many studies have examined these topics, however only a few studies have directly evaluated real world applications of Standard 241 and analyzed the impact on energy consumption.

The goal of this white paper is to translate these findings into clear, accessible insights for readers—whether or not they are experts—so that building owners, designers, and technology providers can better understand how to implement Standard 241 in practical and energy efficient ways.

Indoor air quality (IAQ) has become a central priority for building managers, HVAC designers, and policymakers seeking to reduce the spread of airborne infectious agents. While ventilation and filtration have long been considered the foundation of healthy indoor environments, recent research highlights the importance of combining multiple technologies—including germicidal ultraviolet (GUV/UVGI), portable air cleaners, and hybrid strategies—to create effective, energy-efficient solutions.

In 2023, ASHRAE introduced Standard 241 – Control of Infectious Aerosols, establishing the first global framework for reducing the airborne transmission of pathogens in buildings. Building upon decades of IAQ research, Standard 241 defines new performance-based metrics that shift the focus from ventilation alone to the broader concept of Equivalent Clean Air (ECA).

A new peer-reviewed article published in Building and Environment (2025), titled “Analysis of strategies to meet ASHRAE S241 infectious aerosol control targets by space type and region using EnergyPlus simulations”, investigates how different building types and climate zones can meet Standard 241 requirements through a combination of strategies simulated with EnergyPlus™.

2. OVERVIEW OF ASHRAE STANDARD 241

2.1 Purpose of the Standard

Standard 241 provides minimum requirements for reducing the risk of airborne infectious disease transmission in buildings. Unlike traditional ventilation guidelines, it introduces a performance-based approach that considers several mechanisms able to supply pathogen-free or pathogen-reduced air.

2.2 The Concept of Equivalent Clean Air (ECA)

The core of the standard is Equivalent Clean Airflow (ECA), defined as the combined clean air supplied through:

- outdoor air ventilation,

- mechanical filtration,

- portable air cleaners (PACs),

- ultraviolet germicidal irradiation (GUV/UVGI),

- other air disinfection technologies.

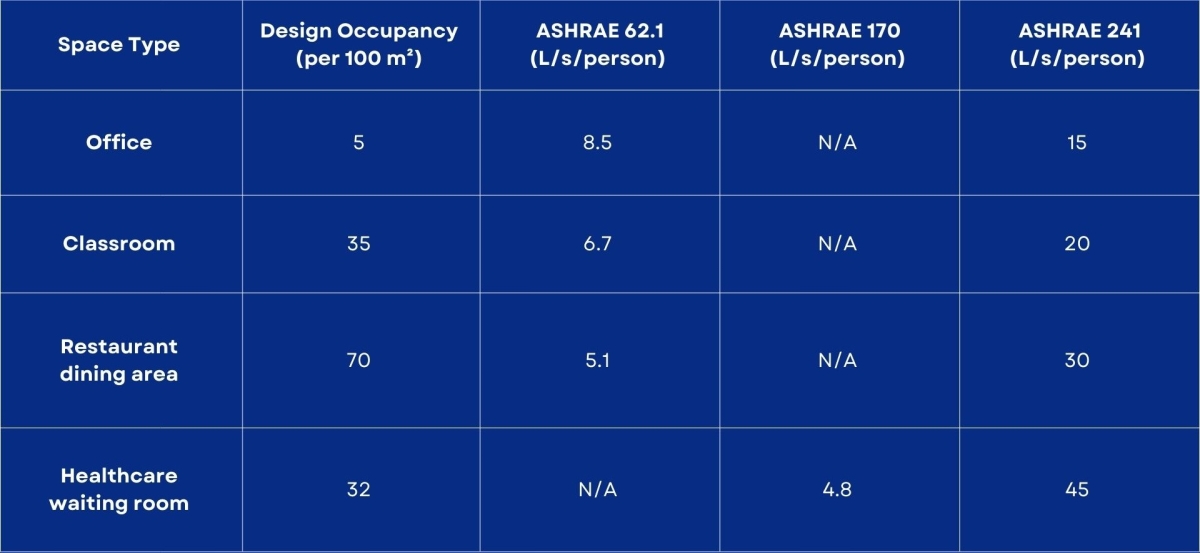

2.3 Requirements by Space Type

Standard 241 establishes ECA targets based on occupancy type, activity, and risk level. Typical ECA values range from:

- 10 L/s per person (low risk / standard occupancy)

- up to 40–45 L/s per person (dense or high-risk environments)

- It formalizes air cleaning strategies that go beyond ventilation.

- It allows flexibility in combining technologies.

- It supports energy-efficient approaches, particularly in climates where increasing outdoor air volume is costly.

- It enables clearer risk management strategies for schools, healthcare, offices, and public spaces.

The 2025 study published by the Pacific Northwest National Laboratory (PNNL) represents one of the most comprehensive efforts to date to translate the theoretical framework of ASHRAE Standard 241 into practical, quantifiable building strategies. Instead of examining technologies in isolation, the authors develop a rigorous simulation-based methodology to understand how combinations of ventilation, filtration, and disinfection technologies—including GUV—can meet or exceed Equivalent Clean Air (ECA) requirements across a variety of space types and climate zones.

3.1 Research Foundation and Objectives

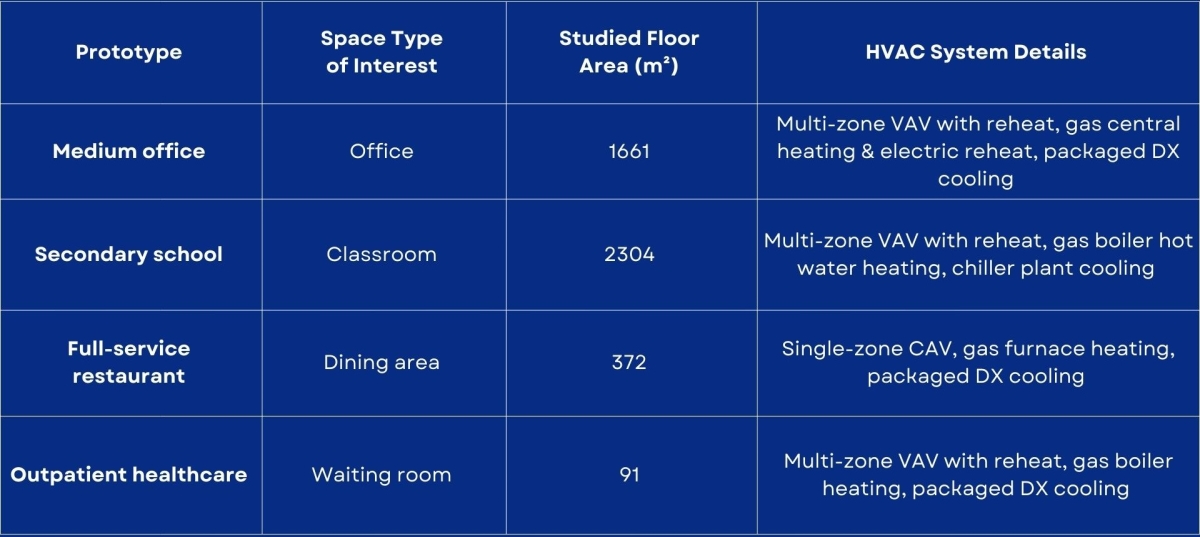

The PNNL team grounds its work in the new performance-based structure of Standard 241, which recognizes that infectious aerosol control cannot rely solely on traditional ventilation. Their objective is not merely to compute ECA values, but to determine how real-world systems behave under varying climatic, architectural, and operational conditions. They evaluate multiple space categories—offices, classrooms, clinics, residential units, commercial spaces—each with unique occupancy densities and activity patterns that influence infectious aerosol dynamics.

The study also aims to provide policymakers and building designers with a deeper understanding of how different combinations of indoor air quality (IAQ) interventions can achieve policy compliance without compromising energy performance or thermal comfort.

3.2 Methodological Approach

The researchers employ EnergyPlus™, one of the most advanced and validated building performance simulation engines, to model energy exchange, airflow behavior, filtration efficiency, GUV effectiveness, and aerosol removal rates. Climate-specific datasets allow the simulations to reflect real-world heating and cooling loads across diverse geographic zones.

Unlike many previous studies that evaluate only ventilation rate increases, the PNNL work integrates dynamic interactions between HVAC systems and disinfection technologies. It models scenarios where outdoor air intake is expanded, filtration is upgraded (e.g., from MERV 8 to MERV 13 or higher), HVAC-integrated GUV is added, portable systems are deployed, or upper-room GUV is installed. Each scenario is quantified not only in its contribution to ECA, but also in its energy impact—an essential dimension of Standard 241 compliance.

Table 1. Example Comparison of ECAᵢ Levels Across Standards

Measures Examined in the Study

- Increased Outdoor Air Ventilation:Outdoor airflow at the AHU increased by 30% above ASHRAE 62.1/170 baselines.

- HVAC Filtration: MERV 13 used for most analyses; MERV 14 required for healthcare waiting; MERV 8 as baseline. Higher MERV/HEPA not used due to pressure-drop constraints.

- In-Duct GUV: Clean air delivery calculated using airflow, irradiated volume, exposure time, and UV dose.

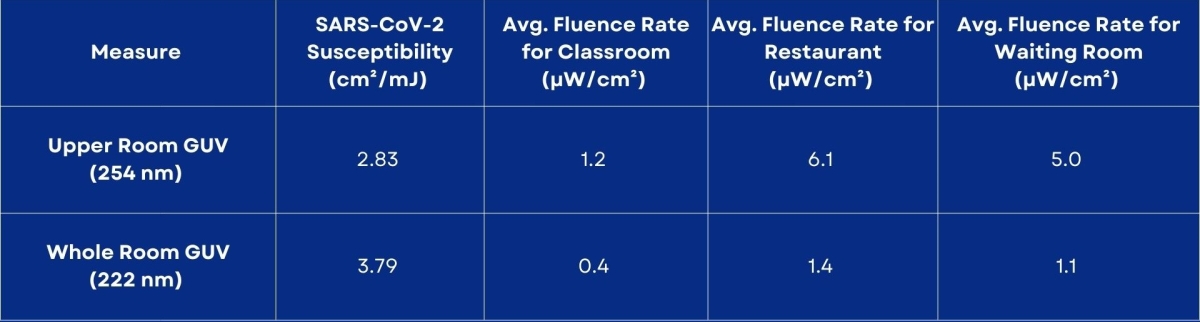

- In-Room GUV: Maximum fluence limits: 75 μW/cm² for upper-room 254 nm; 1.5 μW/cm² for whole-room 222 nm.

- Portable Air Cleaners (PACs): Modeled using CADR, energy consumption, and heat dissipation. Maximum CADR ~78 L/s per 20.9 m².

Medium office, secondary school, restaurant dining area, outpatient healthcare—each with unique HVAC configurations influencing S241 compliance potential.

Table 4. Summary of Studied Climate Zones

.jpg) Climate Zones Studied (Table 4)

Climate Zones Studied (Table 4)Seven representative U.S. climate zones were used, ranging from hot/humid Tampa to very cold International Falls.

3.3 Findings and Interpretation

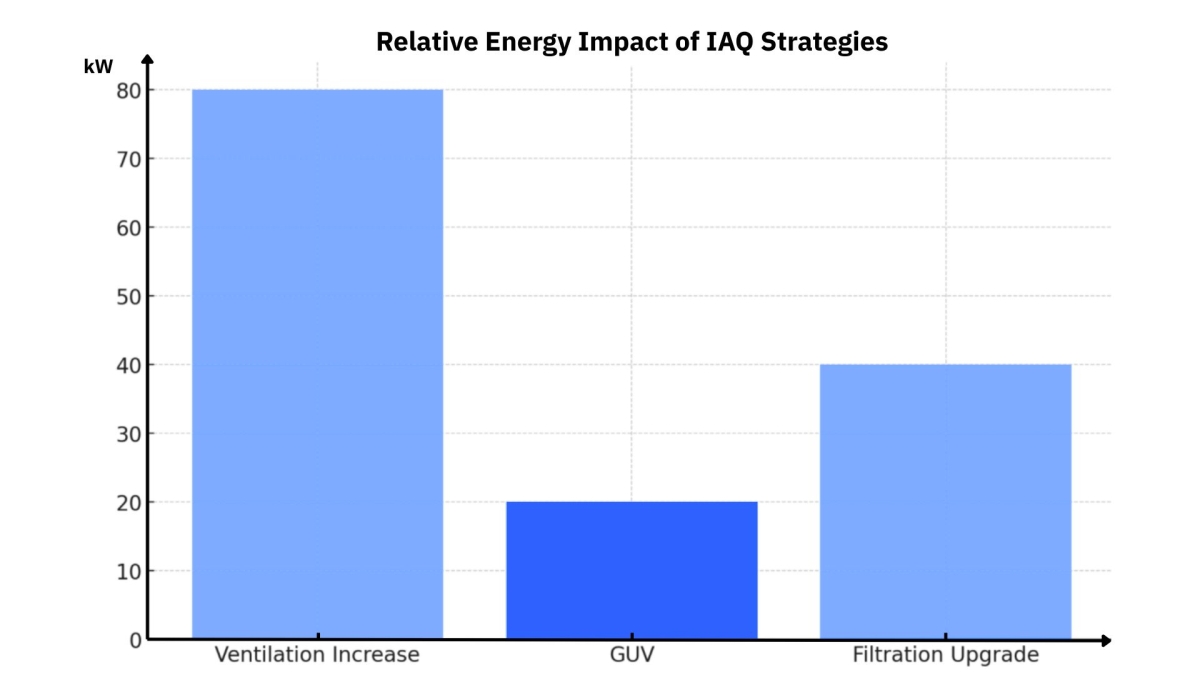

The study’s results reveal that strategies achieving compliance differ substantially depending on climate, building type, and baseline system performance. In many warm or cold climates, increasing outdoor air alone creates substantial energy penalties due to heating or cooling loads. This reinforces the Standard 241 principle that ECA should be met through multiple pathways rather than ventilation alone.

PNNL’s analysis shows that GUV—whether installed in ductwork or as upper-room systems—plays a decisive role in meeting ECA targets efficiently. Because GUV inactivates pathogens without requiring the conditioning of additional outdoor air, it offers an exceptionally favorable ratio of energy use to clean air delivered. In some scenarios, GUV becomes the only feasible option to meet higher ECA thresholds without costly HVAC overhauls.

The study also emphasizes that portable HEPA systems and improved filtration can contribute meaningfully, particularly in small or moderately occupied spaces. However, they often lack the capacity to achieve compliance in large or densely occupied rooms—an area where GUV demonstrates significant advantages.

By articulating these outcomes numerically through EnergyPlus simulations, the PNNL work elevates the discussion around IAQ technologies from anecdotal judgments to precise performance-based decision-making.

Table 6. GUV Design Adjustments When Using SARS-CoV-2 as the Challenge Agent

Considering Alternative Pathogens (Table 6)

When SARS-CoV-2 is used as the challenge agent rather than MS2, GUV requirements drop dramatically due to higher susceptibility. Fluence requirements decrease by 93–98% for upper-room GUV and 27–73% for whole-room GUV. This reduces energy use and allows compliance in high-target spaces where MS2-based designs struggle.

4. IMPLICATIONS FOR BUILDING OPERATORS AND TECHNOLOGY PROVIDERS

4.1 Designing Systems for Compliance

- Meeting ASHRAE 241 requires a multilayered approach.

- GUV plays an increasingly central role due to its effectiveness and operational cost advantages.

- Proper sizing of ECA contributions from each technology is essential.

The findings support strong future adoption of: GUV systems (upper-room, in-duct, and whole-room), advanced filtration solutions, and intelligent hybrid IAQ control systems.

4.3 Energy and Sustainability Considerations

Compliance with Standard 241 can be achieved without increasing energy consumption, if hybrid strategies are applied. GUV offers one of the best energy-to-clean-air ratios among available technologies.

5. CONCLUSIONS

ASHRAE Standard 241 marks a pivotal shift in how buildings address infectious aerosol control. The 2025 EnergyPlus study reinforces the need for integrated IAQ strategies combining ventilation, filtration, GUV, and portable cleaning technologies.

For companies creating IAQ solutions—including UVGI manufacturers—these findings validate the importance of multi-technology approaches and highlight the strategic role of GUV in reaching high levels of Equivalent Clean Air while maintaining energy efficiency.

%20contributions%20from%20different%20strategies.jpg)

References

Cary A. Faulkner, Cerrina Mouchref, Belal Abboushi, Meghan K. McNulty, Timothy I. Salsbury, Brett C. Singer, Michael D. Sohn, Gabe Arnold, Analysis of strategies to meet ASHRAE S241 infectious aerosol control targets by space type and region using EnergyPlus™ simulations, Building and Environment, Volume 287, Part B, 2026, 113875, ISSN 0360-1323, https://doi.org/10.1016/j.buildenv.2025.113875. (https://www.sciencedirect.com/science/article/pii/S0360132325013459)

FULL ARTICLE HERE: Analysis of strategies to meet ASHRAE S241 infectious aerosol control targets by space type and region using EnergyPlus™ simulations - ScienceDirect

ASHRAE (2023). ANSI/ASHRAE Standard 241-2023: Control of Infectious Aerosols. ASHRAE.

ASHRAE (2023). ASHRAE Guideline 41P – Quantifying Equivalent Clean Air.

Bruns, R. et al. (2023). Energy and cost implications of UVGI compared to ventilation under ASHRAE 241 targets. ASHRAE Technical Resources.

A. Buonomano, C. Forzano, G. Giuzio, A. Palombo, New ventilation design criteria for energy sustainability and indoor air quality in a post COVID-19 scenario, Renew. Sustain. Energy Rev. 182 (2023) 113378.

M.P. Halloran, Cost-Effectiveness Of Various ASHRAE Standard 241-2023 Compliance Methods, ASHRAE J. 66 (6) (2024).

M. Zaatari, A. Goel, J. Maser, Why Equivalent Clean Airflow Doesn’t Have To Be Expensive, Ashrae J. 65 (9) (2023) 18–24.

R. Bruns, Cost-Benefit Analysis of ASHRAE Standard 241, Ashrae J. 65 (10) (2023).

D.B. Crawley, L.K. Lawrie, F.C. Winkelmann, W.F. Buhl, Y.J. Huang, C.O. Pedersen, R.K. Strand, R.J. Liesen, D.E. Fisher, M.J. Witte, et al., EnergyPlus: creating a new-generation building energy simulation program, Energy Build. 33 (4) (2001) 319–331.

C.J. Noakes, M.A.I. Khan, C.A. Gilkeson, Modeling infection risk and energy use of upper-room ultraviolet germicidal irradiation systems in multi-room environments, Sci. Technol. Built Environ. 21 (1) (2015) 99–111.

E.-J. Sarabia-Escriva, V.-M. Soto-Francés, J.-M. Pinazo-Ojer, Mathematical model based on the radiosity method for estimating the efficiency of in-duct UVGI systems, Sci. Technol. Built Environ. 28 (9) (2022) 1255–1269.

contributions from different strategies.jpg)