Regulatory clarity, technical reality and industrial responsibility

The European RoHS Directive has brought the use of mercury in electrical and electronic equipment back to the center of regulatory and industrial debate, including traditional UV-C lamps.

For those of us who design disinfection systems for air, water and surfaces in critical environments, this is not a theoretical issue nor a topic for commercial communication. It is a technical and regulatory matter.

In this context, the growing circulation of messages portraying UV-C lamps as an “outdated” technology or as being close to an inevitable “mercury ban” is a cause for concern. Linking normal technological and environmental evolution to a ban that has not been decided and does not currently exist creates confusion, distorts market perception and risks generating unjustified alarm.

THE ROHS DIRECTIVE AND UV-C LAMPS

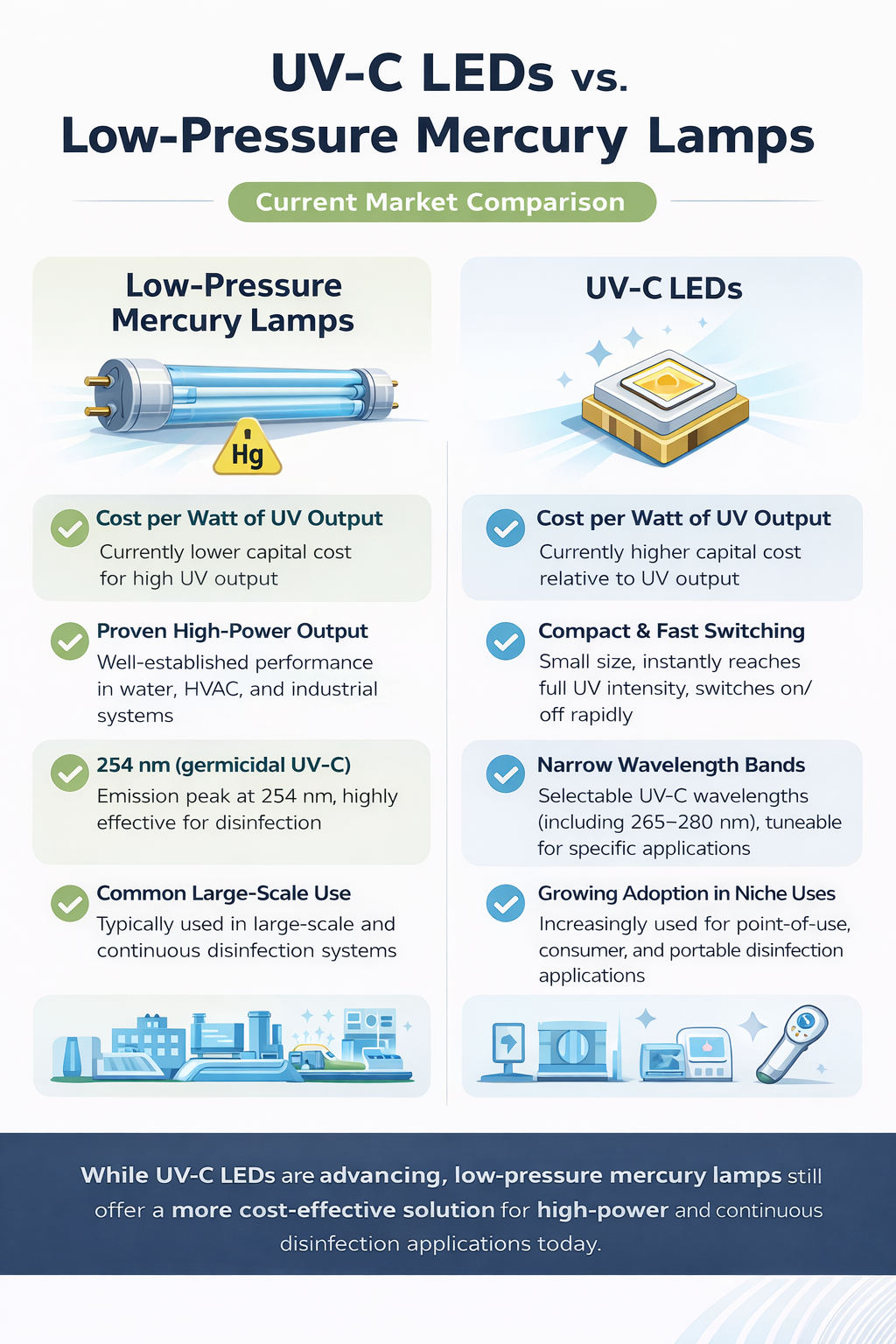

RoHS (Restriction of Hazardous Substances) limits the use of certain hazardous substances, including mercury. Low- and medium-pressure UV-C lamps use a controlled quantity of mercury to generate germicidal radiation at 254 nm, which remains today a benchmark for effectiveness and reliability in professional applications.

An important point often overlooked in public debate must be clarified: low-pressure UV lamps are explicitly subject to exemptions under the annexes of international mercury conventions. This is because:

- they contain extremely small quantities of mercury (in the milligram range);

- they are closed systems;

- they do not represent a significant source of global environmental emissions.

The potential future phase-out of RoHS exemptions within the European framework does not stem from new global environmental evidence, but rather from a political choice to encourage the transition toward mercury-free technologies. This is a substantial distinction that must be clearly understood.

As of today, no definitive decision regarding a general ban has been adopted. RoHS exemptions are assessed and renewed on a case-by-case basis, particularly when technically equivalent alternatives are not yet available for critical public health and safety applications.

Presenting a ban as inevitable means transforming a regulatory hypothesis into a normative certainty that, at present, does not exist.

254 nm: WHY IT REMAINS THE TECHNICAL REFERENCE

Low-pressure lamps operating at 254 nm still represent the gold standard of UV disinfection.

The reason is technical: the wavelength of 254 nm corresponds to the peak germicidal efficiency per joule emitted. This allows high microbiological effectiveness with an optimal balance between installed power, irradiation uniformity and long-term reliability.

In high-power applications — large HVAC systems, air treatment in AHUs, high-flow water treatment plants and continuous industrial processes — this balance remains a decisive parameter.

At present, UV-C LED sources do not yet achieve the same overall performance as traditional mercury lamps in these scenarios.

Recognizing this does not mean opposing innovation. It means accurately describing the current state of the art.

LED TECHNOLOGY: REAL EVOLUTION, DIRECT EXPERIENCE

It is important to clarify that Light Progress has been designing UV-C LED systems since 2014, when this technology was still at an early stage and the market was not yet mature.

Over the years, we have developed LED devices for water treatment, solutions dedicated to small medical devices, as well as prototypes and system architectures for industrial, food and pharmaceutical applications. Our approach has never been ideological; it has always been engineering-driven and based on real testing.

In recent years, LED technology has made significant progress in terms of reliability, stability and cost reduction. The ability to operate at different wavelengths represents a relevant advantage in specific applications.

However, oversimplification must be avoided. Spectral flexibility does not automatically translate into overall superiority compared to traditional 254 nm lamps.

In high-power applications — large HVAC installations, air treatment in AHUs, high-flow water systems or continuous industrial processes — factors such as radiation intensity, irradiation uniformity and long-term performance stability are critical. In these contexts, LED sources do not yet match the overall performance of traditional mercury lamps.

Being transparent about this does not slow innovation. On the contrary, it supports responsible technological development.

LED technology is continuously evolving and will play an increasingly important role. However, it does not yet represent a universal and direct replacement for high-power UV-C lamps in every application scenario.

POSSIBLE RESTRICTIONS: A MATTER OF BALANCE

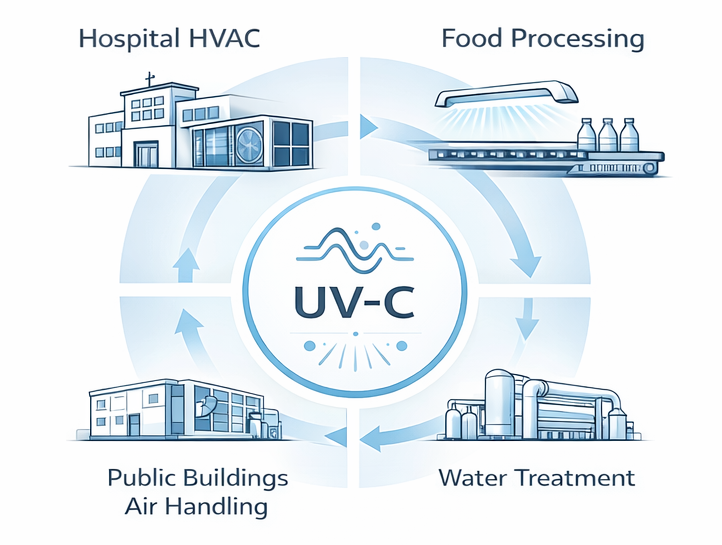

Any hypothesis of progressive restriction must be carefully evaluated. When discussing high-power UV lamps, we are referring to technologies used in:

- hospital environmental hygiene;

- HVAC sanitation;

- food processing safety;

- drinking water quality;

- microbiological control in food and pharmaceutical production.

The phase-out of mercury in UV lamps creates technical and economic challenges, as mercury remains a highly efficient and stable UV source. Developing mercury-free alternatives requires significant R&D.

UV LEDs are a leading alternative, offering longer lifetimes, lower energy use, and instant start-up. However, they still cannot fully match mercury vapor lamps in high-performance applications, particularly in UV-B, UV-C, and water disinfection.

Other options, such as excimer lamps, provide mercury-free solutions for specific uses.

While demand for environmentally friendly technologies is rising, a full ban on UV lamps is uncertain. A phased approach is likely, starting with low-wattage UVA lamps, while high-wattage and UVB/UVC lamps may remain in use for now.

CONSISTENCY WITH OUR MISSION

The regulatory transition represents evolution, not disruption. This is a position we firmly maintain.

We believed in UV lamps when they were still a niche technology. We began designing LED systems in 2014, when the market was not yet mature.

We continue to develop LED solutions, new optical architectures and hybrid systems for the applications of tomorrow.

Progress means innovating, but it also means ensuring continuity, safety and performance in critical applications.

Technological transition must be guided by technical data, not by simplifications. When alternatives offer real equivalence in terms of germicidal effectiveness, reliability and large-scale application sustainability, replacement will occur naturally.

Until then, technical responsibility requires clarity, rigor and the protection of public health.

For further technical clarification or application-specific assessments, our commercial and technical team is fully available: please contact us at info@lightprogress.it

References

Bolton, J. R., & Linden, K. G. (2003). Journal of Environmental Engineering, 129(3), 209–215.

Directive 2011/65/EU (RoHS II). Official Journal of the European Union.

European Commission. RoHS Annex III – Exemptions.

Kneissl, M. et al. (2019). Nature Photonics, 13, 233–244.

Kowalski, W. (2009). Ultraviolet Germicidal Irradiation Handbook. Springer.

UNEP (2013). Minamata Convention on Mercury.

U.S. EPA (2006). Ultraviolet Disinfection Guidance Manual.

Welch, D. et al. (2018). Scientific Reports, 8, 2752.

WHO (2017). Guidelines for Drinking-water Quality.

Würtele, M. A. et al. (2011). Water Research, 45(3), 1481–1489.

.png)