WHAT UVLON IS, THE BENEFITS IT OFFERS, AND WHY IT WILL BECOME A STANDARD OF SAFETY AND QUALITY FOR UV-C SYSTEMS

Designed to become the new standard for UV-C applications, UVLON® is a heat-shrink protective sleeve applied directly to the glass of our UV-C lamps, combining strength, reliability and performance.

In this article, we explain what UVLON® is and the benefits it delivers.

WHAT IS UVLON

FEP is an inert, transparent fluoropolymer approved for food contact according to FDA regulations, making it suitable for applications in the food, pharmaceutical and medical sectors.

The sleeve allows high UV-C wavelength transmission, preserving treatment effectiveness without compromising system safety.

The FEP coating makes lamps safer to handle, allowing bare-hand contact during installation and maintenance, while providing a smooth surface that is easy to clean and resistant to aggressive and chemically demanding environments.

UVLON® also protects lamps from thermal fluctuations, particularly low temperatures, helping maintain optimal performance and improving overall operational reliability.

To ensure uniform and controlled application, Light Progress has developed a proprietary automated machine that performs fully mechanized and precise heat-shrinking. This exclusive process increases protection robustness and makes Light Progress lamps a global benchmark for reliability and durability.

In UV-C systems, preventing lamp breakage is not optional—it is a prerequisite for safe operation.

For this reason, starting in 2026,UVLON® becomes the standard: lamp protection is no longer an option, but an integral part of UV-C systems.

.png)

THE ADVANTAGES – ROI, efficiency and compliance

By protecting the lamp, UVLON® reduces breakage, replacements and downtime. The result is longer lamp life and an immediate return on investment.

Uninterrupted production

In the event of breakage, the sleeve contains glass fragments and prevents contamination, rejects and line shutdowns—an essential requirement in regulated sectors such as food, pharmaceutical, medical and HVAC.

Compliance and brand protection

UVLON® supports compliance with international standards (FDA, IP44) and reduces the risk of non-compliance, product recalls and legal disputes, directly protecting brand reputation.

Reliable performance in harsh environments

The FEP sleeve resists wear, aggressive chemicals and demanding operating conditions, ensuring consistent performance and reducing unplanned maintenance.

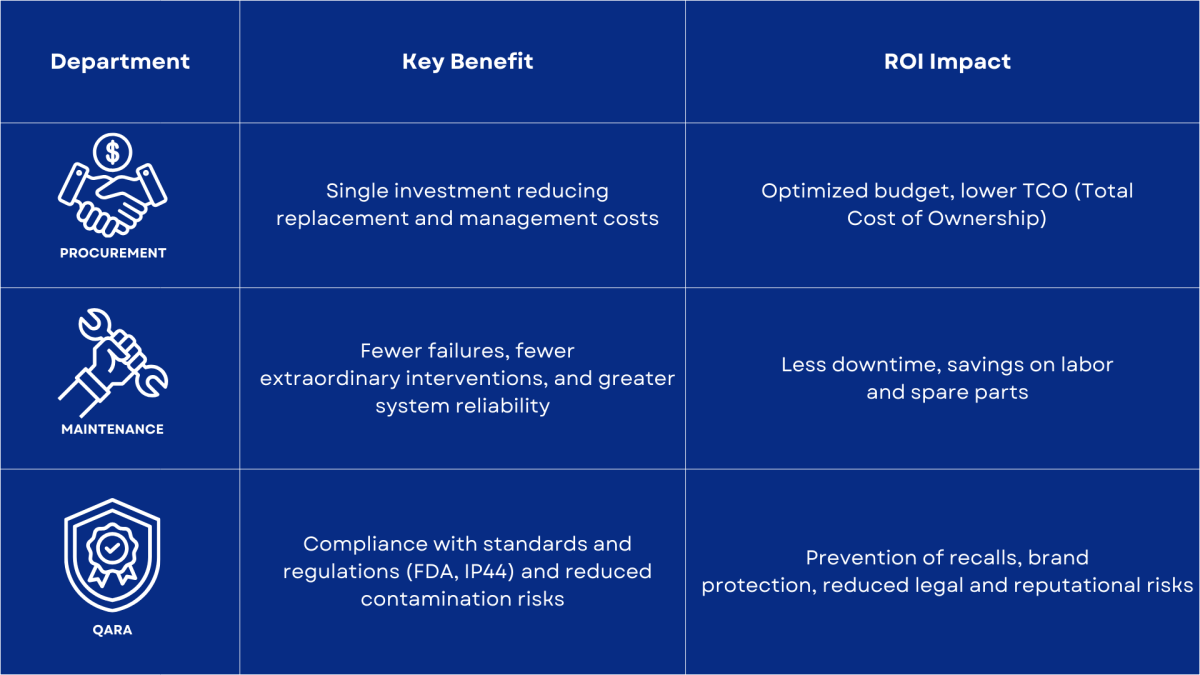

Benefits by department:

AN OPTION TODAY, A STANDARD TOMORROW

REGULATIONS AND RESPONSIBILITY

For machine manufacturers, this means more robust and easier-to-integrate solutions.

For end users, it means greater safety, reduced maintenance and higher operational reliability.

ACCURACY IN PERFORMANCE CALCULATIONS

It is important to note that our microbial inactivation calculations and UV-C system performance software already take the use of UVLON® into account.

As a result, efficacy values remain unchanged and fully reliable.

Integrating UVLON® as a standard adds value and eliminates risk.

Download the official UVLON® declaration: a signed reference document providing certified and reliable information.

For further technical details, personalized consultancy, or to speak directly with our technical department, please contact us at info@lightprogress.it

▶ Guarda il video

▶ Guarda il video