(2 minutes read. Download complete article: DOWNLOAD PDF)

At a glance

Upper Air disinfection: the smart, safe, energy-efficient way to keep IAQ at the highest level. UV-FLOW is the ultimate indoor air disinfection solution, and it makes it easy to apply ASHRAE GPC 37, the new Standard for GUV Commissioning.

Key metrics

Lake Hills Church facilities includes a big Worship Center with 1,200 seats, nurseries for kids aged 0-2, Kids Building dedicated to children 3-12 with classes and large gathering areas, a Student Building as well as offices and a warehouse.

Challenges

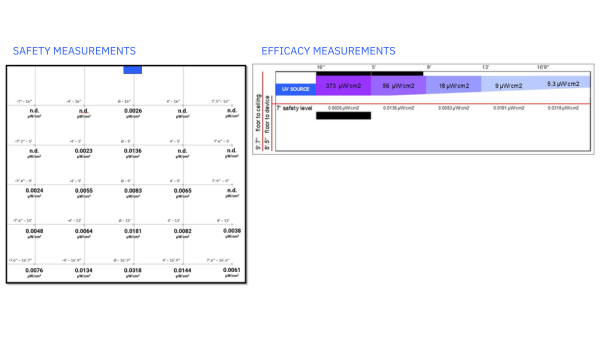

The goal was to reduce the risk of airborne infections and illnesses where ventilation is limited and occupants are more sensitive, such as newborns and children. The main challenge was to commission the project according to the ASHRAE standard and to provide an installation in a large environment and in small rooms, while keeping an eye on efficiency and safety.

Solutions

UV-FLOW-WL and UV-FLOW-CL are “Upper AIr” UV systems installed near the ceiling of a room, where they create a disinfection zone of UV light. The air in the room is circulated through this zone by natural or mechanical ventilation. As the air passes through the zone, the UV light inactivates any airborne pathogens that are present. The air then returns to the lower part of the room, safe and clean.

Benefits

- Protect Health while ensuring Safety: by providing enough GUV energy to treat entire areas, UV-FLOW models ensured the optimal level of efficacy, while maintaining the UV-C level under total control for safety.

- Innovate with ease and simplicity: the perfect type of Upper Air UV-C system, UV-FLOW can be easily adapted to any environment and is easy to install in different spaces.

- Increase IAQ without increasing Energy Costs: UV-FLOW Upper Air is a more efficient alternative to raise IAQ above the standard without increasing HVAC energy consumption.

The Commissioning process embedded in the GPC 37 Guideline (ANSI/ASHRAE/IES 202 and 90.1) maps the entire commissioning process from needs assessment to implementation to build the project brief. The purpose is to plan, design, install, test, operate and maintain to meet requirements.

OUR EXPERTISE

Ruling out large environments that were not regularly populated or had plenty of fresh air ventilation, we identified 5 potential areas for application in the Kids Building and Worship Center based on room usage, characteristics, and primary occupants. The budget priority reduced us to 3 areas mitigating risk for the oldest and youngest in the community:

- 3 Nurseries Rooms (16x16 ft - 4,8x4,8 m)

- Club K12 Room (45x49 ft - 13,7x14,9 m)

.png)

Beyond producing CAD Drawings, we modelled/calculated dosage and product performance using goniospectrophotometry (i.e., IES files) to select the products and placement. Devices were chosen by wattage based on calculations of both volume and surface coverage dosage. From Design to Installation there were also considerations for a variety of customer-centric issues, such as usability, integration with other behaviors, practices, or protocols as well as aesthetic considerations.

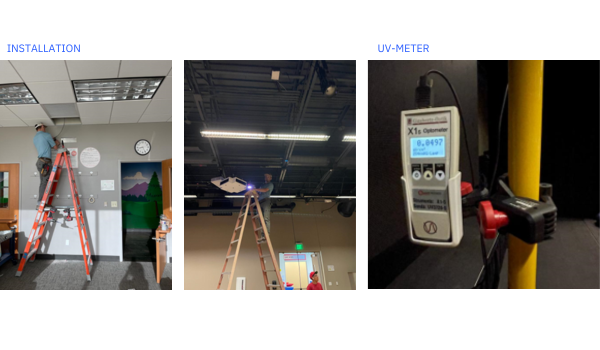

We provided installation support training the electricians on safety, we educated them on the project intent, design constraints, and exact positioning. Fortunately, we did not discover physical realities tha would have changed economics.

We decided to operate the units from separate switches that were clearly marked on the wall and to add safety labels to ensure that everyone was aware of the presence of UV-C systems in the environment.

We conducted a performance and safety test using a UV-C meter and following the photobiological safety test of UL standard. It verifies the installation height and angle and sets the thresholds.

After a month of use, we interviewed the facility manager for feedback and received very enthusiastic comments about how much the staff appreciated the attention to their health and how practical the systems were to use.

CONCLUSION:

Customer greatly enhanced its IAQ and get rid of airborne microbes in its most critical areas without affecting the existing ventilation system.